The success of the Iranian knowledge-based company in the reverse engineering of the passenger plane engine

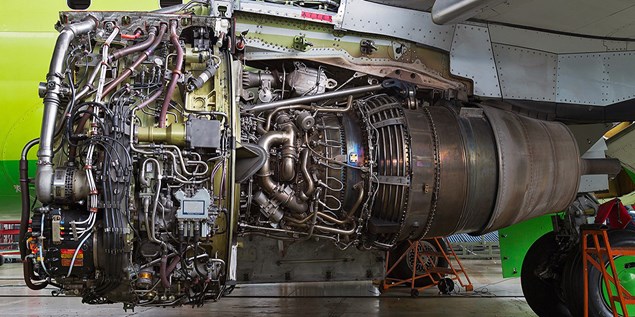

The Iranian specialists of a knowledge-based company succeeded in reverse engineering the CFM56 jet engine as the world's most popular passenger plane engine with round-the-clock efforts .

According to Kayhan : Mani Rezvani, one of the directors of this knowledge-based company, said in an interview with Tasnim news agency about the reverse engineering of the passenger plane engine: The CFM56 turbofan engine was chosen as the main project of this team, which was the first step in the complete engine reverse engineering process.

He continued: At present, this engine is the most widely used turbofan passenger aircraft engine in the world that has been built, and today it holds the record of flight hours in the entire passenger airline fleet in the world, and it is mainly installed in the family of Airbus A319, A320 and A340 four-engines and Boeing 737 classics. .

The director of this knowledge-based company noted: After seven years of continuous efforts, we have achieved the full design knowledge of this engine. All stages of the compressor blades of this engine are reverse engineered. Most of the components of the combustion chamber of the engine and its turbine section (Hot Section) are also made. The construction of other side parts of this engine, including the engine control unit (FADEC), sensors, various precise measurement and control equipment, hydraulic and pneumatic valves and pumps, gearbox, data transmission system and cabling, etc., has also been completed.

He said: The design and manufacture of the fan blades has also been completed and now we are obtaining the flight qualification certificate from the Civil Aviation Organization for all the manufactured parts.

The director of this knowledge-based company added: The reverse engineering of this engine has been completely done in terms of design knowledge, but for the prototype, in terms of construction, there has been about 33% physical progress so far. Of course, in the matter of mass production of this engine, there must be customers.

Domestic aircraft repair

Rezvani stated that at the same time as reverse engineering and the construction of this engine began, the issue of repairs of the CFM engine family also began, he continued: Currently, this knowledge-based company is specialized in three areas, including engine repairs and engine accessories (MRO), engine design and engineering. (DOA) and manufacture parts (POA) and serves domestic airlines.

Pointing to the strategic importance of acquiring design knowledge in the field of air vehicle engines, he announced: Today, we are at the edge of technology and knowledge of design and manufacturing of air turbine engines. If we want to invest in the field of manufacturing all kinds of passenger plane engines; The dimensions of this investment will be very large and it needs actual customers, which is not possible in the country at the present time, and domestic airlines are not able to place orders of this size.

The director of this knowledge-based company added: "In the international market, we should also go for the international aviation industry certificates for the engine, and now we need time to start this process." Currently, we are investigating the communication and processes of obtaining the CFM engine family manufacturing and repair certificate from the European Union Aviation Safety Agency (EASA). The process of obtaining certificates for the manufactured parts of this engine is longer than the process of obtaining the certificate for repairs of the mentioned engine due to the technical complexities and aviation safety requirements.

Rezvani clarified: In this process, the performance of the manufactured parts sample must be fully evaluated in the actual operating conditions of the engine to show that the manufactured part meets all the design expectations and has the necessary competence and safety to be installed on the passenger plane engine.